常常在手持量測工具的開發中,會使用到LCD來顯示量測資訊,如電壓等,在這邊就簡單的介紹我之前用來開發某量測工具使用LCD的控制方式!

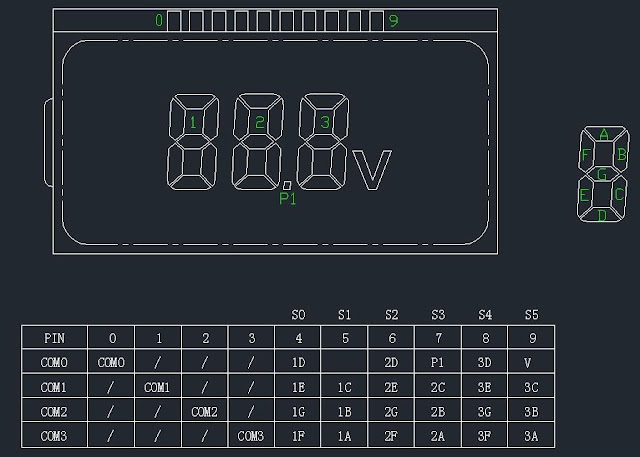

由於並非所有STM32 MCU都有LCD顯示的功能,因此這邊選擇STM32L100C6U6A為例,假設要來點亮88.8V這樣字符的LCD,88.8V需要23個點,假設選擇4COMx6SEG共有24 pixels可以滿足23個點的需求,所以會占用STM32L100C6U6A 10 pin I/O(4COM

+ 6SEG),LCD設計圖如下:

#define

LCD_SEG0_Pin GPIO_Pin_1

#define

LCD_SEG0_GPIO_Port GPIOA

#define

LCD_SEG1_Pin GPIO_Pin_2

#define

LCD_SEG1_GPIO_Port GPIOA

#define

LCD_SEG2_Pin GPIO_Pin_3

#define

LCD_SEG2_GPIO_Port GPIOA

#define

LCD_SEG3_Pin GPIO_Pin_6

#define

LCD_SEG3_GPIO_Port GPIOA

#define

LCD_SEG4_Pin GPIO_Pin_7

#define

LCD_SEG4_GPIO_Port GPIOA

#define

LCD_SEG5_Pin GPIO_Pin_0

#define

LCD_SEG5_GPIO_Port GPIOB

#define

LCD_COM0_Pin GPIO_Pin_8

#define

LCD_COM0_GPIO_Port GPIOA

#define

LCD_COM1_Pin GPIO_Pin_9

#define

LCD_COM1_GPIO_Port GPIOA

#define

LCD_COM2_Pin GPIO_Pin_10

#define

LCD_COM2_GPIO_Port GPIOA

#define

LCD_COM3_Pin GPIO_Pin_9

#define

LCD_COM3_GPIO_Port GPIOB

void

LCD_Config(void)

{

LCD_InitTypeDef

LCD_InitStructure;

GPIO_InitTypeDef

GPIO_InitStructure;

RCC_AHBPeriphClockCmd(RCC_AHBPeriph_GPIOA

| RCC_AHBPeriph_GPIOB, ENABLE);

GPIO_PinAFConfig(GPIOA,

GPIO_PinSource8, GPIO_AF_LCD); // com0

GPIO_PinAFConfig(GPIOA,

GPIO_PinSource9, GPIO_AF_LCD); // com1

GPIO_PinAFConfig(GPIOA,

GPIO_PinSource10, GPIO_AF_LCD); // com2

GPIO_PinAFConfig(GPIOB,

GPIO_PinSource9, GPIO_AF_LCD); // com3

GPIO_PinAFConfig(GPIOA,

GPIO_PinSource1, GPIO_AF_LCD); // seg0

GPIO_PinAFConfig(GPIOA,

GPIO_PinSource2, GPIO_AF_LCD); //

seg1

GPIO_PinAFConfig(GPIOA,

GPIO_PinSource3, GPIO_AF_LCD); // seg2

GPIO_PinAFConfig(GPIOA,

GPIO_PinSource6, GPIO_AF_LCD); // seg3

GPIO_PinAFConfig(GPIOA, GPIO_PinSource7,

GPIO_AF_LCD); // seg4

GPIO_PinAFConfig(GPIOB,

GPIO_PinSource0, GPIO_AF_LCD); // seg5

GPIO_InitStructure.GPIO_Pin

= LCD_SEG0_Pin | LCD_SEG1_Pin |

LCD_SEG2_Pin | LCD_SEG3_Pin | LCD_SEG4_Pin

| LCD_COM0_Pin |

LCD_COM1_Pin | LCD_COM2_Pin;

GPIO_InitStructure.GPIO_Mode

= GPIO_Mode_AF;

GPIO_InitStructure.GPIO_OType

= GPIO_OType_PP;

GPIO_InitStructure.GPIO_Speed

= GPIO_Speed_2MHz;

GPIO_InitStructure.GPIO_PuPd

= GPIO_PuPd_NOPULL;

GPIO_Init(GPIOA,

&GPIO_InitStructure);

GPIO_InitStructure.GPIO_Pin

= LCD_SEG5_Pin | LCD_COM3_Pin;

GPIO_InitStructure.GPIO_Mode

= GPIO_Mode_AF;

GPIO_InitStructure.GPIO_OType

= GPIO_OType_PP;

GPIO_InitStructure.GPIO_Speed

= GPIO_Speed_2MHz;

GPIO_InitStructure.GPIO_PuPd

= GPIO_PuPd_NOPULL;

GPIO_Init(GPIOB,

&GPIO_InitStructure);

/*!< Configure the LCD interface */

RCC_APB1PeriphClockCmd(RCC_APB1Periph_LCD,

ENABLE);

LCD_BlinkConfig(LCD_BlinkMode_Off,

LCD_BlinkFrequency_Div8);

LCD_InitStructure.LCD_Prescaler =

LCD_Prescaler_4;

LCD_InitStructure.LCD_Divider =

LCD_Divider_16;

LCD_InitStructure.LCD_Duty = LCD_Duty_1_4;

}

由於一個com會對應到44 seg,一個com對seg共需要2個32 bit(S00~S43,其餘空白)的大小來存放顯示資料,但LCD圖面只用到4COMx6SEG,因此只須宣告一個32bit變數來對應S00~S31,由於使用了4COM所以必須宣告四個變數如下:

uint32_t

LCD_COM0_SEGx = 0;

uint32_t

LCD_COM1_SEGx = 0;

uint32_t

LCD_COM2_SEGx = 0;

uint32_t

LCD_COM3_SEGx = 0;

LCD register

map and reset values

#define

COMx_S00 0x00000001 << 0

#define

COMx_S01 0X00000001 <<

1

#define

COMx_S02 0X00000001 <<

2

#define

COMx_S03 0X00000001 <<

3

#define

COMx_S04 0X00000001 <<

4

#define

COMx_S05 0X00000001 <<

5

#define

COM0_S0_S31 0 // COM0-S0~S31

#define

COM1_S0_S31 2 // COM1-S0~S31

#define

COM2_S0_S31 4 // COM2-S0~S31

#define

COM3_S0_S31 6 // COM3-S0~S31

enum

{

CHAR_0 = 0,

CHAR_1 = 1,

CHAR_2 = 2,

CHAR_3

= 3,

CHAR_4 = 4,

CHAR_5 = 5,

CHAR_6 = 6,

CHAR_7 = 7,

CHAR_8 = 8,

CHAR_9 = 9,

CHAR_A = 10,

CHAR_a = 10,

CHAR_B = 11,

CHAR_b = 11,

CHAR_C = 12,

CHAR_c = 12,

CHAR_D = 13,

CHAR_d = 13,

CHAR_E = 14,

CHAR_e = 14,

CHAR_F = 15,

CHAR_f = 15,

CHAR_H = 16,

CHAR_h = 16,

CHAR_I = 17,

CHAR_i = 17,

CHAR_J = 18,

CHAR_j = 18,

CHAR_L = 19,

CHAR_l = 19,

CHAR_N = 20,

CHAR_n = 20,

CHAR_O = 21,

CHAR_o = 21,

CHAR_P = 22,

CHAR_p = 22,

CHAR_R = 23,

CHAR_r = 23,

CHAR_S = 24,

CHAR_s = 24,

CHAR_T = 25,

CHAR_t = 25,

CHAR_U = 26,

CHAR_u = 26,

CHAR_Y = 27,

CHAR_y = 27,

CHAR_DESH = 28,

CHAR_NULL = 29

};

#define

DIG1 0

#define

DIG2 1

#define

DIG3 2

#define

DIG4 3

另外我會撰寫LCD的TABLE如下:

//

0, 1, 2, 3, 4, 5, 6, 7, 8, 9, A, b, C, d, E, F, H, I, J, L, n, O, P, r, S, t,

U, Y, -, NULL

const

uint8_t LCD_Digit_Table[30] = {0x3F, 0x06, 0x5B, 0x4F, 0x66, 0x6D, 0x7D, 0x07,

0x7F, 0x6F,0x77, 0x7C, 0x39, 0x5E, 0x79, 0x71, 0x76, 0x06, 0x0E, 0x38, 0x54,

0x3F, 0x73, 0x50, 0x6D, 0x78, 0X3e, 0x6E, 0x40, 0x00};

由於TABLE屬於常數資料,因此需宣告為const,另外再寫一個用來顯示控制的七結構變數,

union

LCD_Digit

{

uint8_t Byte;

struct

{

unsigned a : 1;

unsigned b : 1;

unsigned c : 1;

unsigned d : 1;

unsigned e : 1;

unsigned f : 1;

unsigned g : 1;

unsigned p_v : 1;

};

}Dig[3]

= {0, 0, 0};

void

LCD_COM0_SEGx_Update(void)

{

LCD_COM0_SEGx = 0;

if(Dig[0].d)

LCD_COM0_SEGx |= COMx_S00; // COM0-SEG0

if(Dig[2].d)

LCD_COM0_SEGx |= COMx_S02; // COM0-SEG2

if(Dig[3].p_v)

LCD_COM0_SEGx |= COMx_S03; // COM0-SEG3

if(Dig[4].d)

LCD_COM0_SEGx |= COMx_S04; // COM0-SEG4

if(Dig[5].p_v)

LCD_COM0_SEGx |= COMx_S05; // COM0-SEG5

return;

}

void

LCD_COM1_SEGx_Update(void)

{

LCD_COM0_SEGx = 0;

if(Dig[0].e)

LCD_COM0_SEGx |= COMx_S00; // COM1-SEG0

if(Dig[0].c)

LCD_COM0_SEGx |= COMx_S01; // COM1-SEG1

if(Dig[1].e)

LCD_COM0_SEGx |= COMx_S02; // COM1-SEG2

if(Dig[1].c)

LCD_COM0_SEGx |= COMx_S03; // COM1-SEG3

if(Dig[2].e)

LCD_COM0_SEGx |= COMx_S04; // COM1-SEG4

if(Dig[2].c)

LCD_COM0_SEGx |= COMx_S05; // COM1-SEG5

return;

}

void

LCD_COM2_SEGx_Update(void)

{

LCD_COM0_SEGx = 0;

if(Dig[0].g)

LCD_COM0_SEGx |= COMx_S00; // COM2-SEG0

if(Dig[0].b)

LCD_COM0_SEGx |= COMx_S01; // COM2-SEG1

if(Dig[1].g)

LCD_COM0_SEGx |= COMx_S02; // COM2-SEG2

if(Dig[1].b)

LCD_COM0_SEGx |= COMx_S03; // COM2-SEG3

if(Dig[2].g)

LCD_COM0_SEGx |= COMx_S04; // COM2-SEG4

if(Dig[2].b)

LCD_COM0_SEGx |= COMx_S05; // COM2-SEG5

return;

}

void

LCD_COM3_SEGx_Update(void)

{

LCD_COM0_SEGx = 0;

if(Dig[0].f)

LCD_COM0_SEGx |= COMx_S00; // COM3-SEG0

if(Dig[0].a)

LCD_COM0_SEGx |= COMx_S01; // COM3-SEG1

if(Dig[1].f)

LCD_COM0_SEGx |= COMx_S02; // COM3-SEG2

if(Dig[1].a)

LCD_COM0_SEGx |= COMx_S03; // COM3-SEG3

if(Dig[2].f)

LCD_COM0_SEGx |= COMx_S04; // COM3-SEG4

if(Dig[2].a)

LCD_COM0_SEGx |= COMx_S05; // COM3-SEG5

return;

}

void LCD_Digit_Display(uint8_t Digit, const unsigned char Table)

{

switch(Digit)

{

case 0 : Dig[0].Byte = Table; break;

case 1 : Dig[1].Byte = Table; break;

case 2 : Dig[2].Byte = Table; break;

case 3 : Dig[3].Byte = Table; break;

default : break;

}

return;

}

void

LCD_Char_Display(const uint8_t *ptr)

{

uint8_t cnt = 0;

uint8_t LCD_Digit[4] = {CHAR_NULL,

CHAR_NULL, CHAR_NULL, CHAR_NULL};

while(*ptr != 0x00)

{

switch(*ptr)

{

case '0':

LCD_Digit[cnt] = CHAR_0;

break;

case '1':

LCD_Digit[cnt]

= CHAR_1; break;

case '2':

LCD_Digit[cnt] = CHAR_2;

break;

case '3':

LCD_Digit[cnt] = CHAR_3;

break;

case '4':

LCD_Digit[cnt] = CHAR_4;

break;

case '5':

LCD_Digit[cnt] = CHAR_5;

break;

case '6':

LCD_Digit[cnt] = CHAR_6;

break;

case '7':

LCD_Digit[cnt] = CHAR_7;

break;

case '8':

LCD_Digit[cnt] = CHAR_8;

break;

case '9':

LCD_Digit[cnt] = CHAR_9; break;

case 'A':

case 'a': LCD_Digit[cnt] =

CHAR_A; break;

case 'B':

case 'b': LCD_Digit[cnt] =

CHAR_B; break;

case 'C':

case 'c': LCD_Digit[cnt] =

CHAR_C; break;

case 'D':

case 'd': LCD_Digit[cnt] =

CHAR_D; break;

case 'E':

case 'e': LCD_Digit[cnt] =

CHAR_E; break;

case 'F':

case 'f': LCD_Digit[cnt] =

CHAR_F; break;

case 'H':

case 'h': LCD_Digit[cnt] =

CHAR_H; break;

case 'I':

case 'i': LCD_Digit[cnt] =

CHAR_I; break;

case 'J':

case

'j': LCD_Digit[cnt] = CHAR_J; break;

case 'L':

case 'l': LCD_Digit[cnt] =

CHAR_L; break;

case 'N':

case 'n': LCD_Digit[cnt] =

CHAR_N; break;

case 'O':

case 'o': LCD_Digit[cnt] =

CHAR_O; break;

case 'P':

case 'p': LCD_Digit[cnt] =

CHAR_P; break;

case 'R':

case 'r': LCD_Digit[cnt] =

CHAR_R; break;

case 'S':

case 's': LCD_Digit[cnt] =

CHAR_S; break;

case 'T':

case 't': LCD_Digit[cnt] =

CHAR_T; break;

case 'U':

case 'u': LCD_Digit[cnt] =

CHAR_U; break;

case 'Y':

case 'y': LCD_Digit[cnt] =

CHAR_Y; break;

case '-': LCD_Digit[cnt] =

CHAR_DESH; break;

default : LCD_Digit[cnt] =

CHAR_NULL; break;

}

ptr++;

cnt++;

}

LCD_Digit_Display(DIG1,

LCD_Digit_Table[LCD_Digit[0]]);

LCD_Digit_Display(DIG2,

LCD_Digit_Table[LCD_Digit[1]]);

LCD_Digit_Display(DIG3,

LCD_Digit_Table[LCD_Digit[2]]);

LCD_Digit_Display(DIG4,

LCD_Digit_Table[LCD_Digit[3]]);

}

}

void

LCD_Integer_Display(int16_t Number)

{

uint8_t LCD_Digit[3] = {CHAR_NULL,

CHAR_NULL, CHAR_NULL, CHAR_NULL};

LCD_Digit[0] = Number / 100;

LCD_Digit[1] = (Number / 10) % 10;

LCD_Digit[2] = Number % 10;

if(LCD_Digit[0] == 0)

{

LCD_Digit[0] = CHAR_NULL;

}

else

LeadZero = 0;

LCD_Digit_Display(DIG1,

LCD_Digit_Table[LCD_Digit[0]]);

LCD_Digit_Display(DIG2,

LCD_Digit_Table[LCD_Digit[1]]);

LCD_Digit_Display(DIG3,

LCD_Digit_Table[LCD_Digit[2]]);

LCD_Digit_Display(DIG4,

LCD_Digit_Table[LCD_Digit[3]]);

}

void

LCD_Handler(void)

{

LCD_COM0_SEGx_Update();

LCD_COM1_SEGx_Update();

LCD_COM2_SEGx_Update();

LCD_COM3_SEGx_Update();

LCD_Write(LCD_RAMRegister_0,

LCD_COM0_SEGx); // COM0SEG0~COM0SEG43

LCD_Write(LCD_RAMRegister_2,

LCD_COM1_SEGx); // COM1SEG0~COM1SEG43

LCD_Write(LCD_RAMRegister_4,

LCD_COM2_SEGx); // COM2SEG0~COM2SEG43

LCD_Write(LCD_RAMRegister_6,

LCD_COM3_SEGx); // COM3SEG0~COM3SEG43

LCD_UpdateDisplayRequest();

/* Wait until the update display is finished

*/

while(LCD_GetFlagStatus(LCD_FLAG_UDD) ==

RESET)

{}

}

假設要顯示12.0V,請先將12.0放大10倍成120,然後套用以下程式,

LCD_Integer_Display(120);

Dig[DIG2].p_v

= 1; // “.”

Dig[DIG3].p_v

= 1; // “V”